Introduction: The Mystery of Mushy Meat

Grinding meat at home is a convenient way to prepare fresh ground beef, pork, or poultry for various recipes. However, a common frustration that many home cooks and chefs encounter is the problem of their meat turning into a mushy paste instead of retaining the desired texture. This can be particularly dishearten ing when you’re aiming for a specific consistency for your burgers, sausages, or ground beef dishes. If you’ve ever found yourself asking, “Why is my grinder mushing the meat?”, you’re not alone. In this article, we will explore the potential causes behind this issue and provide actionable tips for troubleshooting and resolving it. Understanding these factors will help you achieve the perfect grind every time, whether you’re making a juicy burger patty or preparing the ideal stuffing for sausages.

commercial meat grinder

1. The Role of Meat Quality and Type in Grinding

The first step in preventing mushy ground meat starts before the grinder even comes into play: choosing the right meat. Not all meats are suited for grinding in the same way. Fatty cuts like pork belly or beef chuck are more prone to creating a mushy texture, especially if not handled correctly. Fatty tissues are softer, and when ground, they can blend too thoroughly with the leaner muscle fibers, resulting in a paste-like consistency. Conversely, leaner meats such as chicken breast or turkey may not grind well either, leading to a dry, crumbly texture, although this isn’t quite the same as a mushy grind.

Best Practices:

- For a balanced grind, use cuts that have a mix of fat and lean meat. Beef chuck or pork shoulder is ideal for most grinding tasks.

- Avoid overly fatty cuts unless you’re specifically making sausages or other items where the fat is intended to be a significant component of the texture.

- The meat should be chilled, not just for safety reasons, but to ensure that the fat remains solid during the grinding process. If the fat turns too soft, it can smear, leading to mushy meat.

commercial meat grinder

2. The Importance of Properly Chilled Meat

One of the most critical factors in preventing mushy ground meat is ensuring that the meat is chilled properly before grinding. Warm or room-temperature meat is more likely to become mushy during the grinding process because the fat in the meat softens too much. When fat becomes too soft, it has a tendency to smear and clog the grinder, turning the meat into a sticky paste rather than a cleanly ground product.

How to Chill Meat Effectively:

- Pre-Chill the Meat: Prior to grinding, it’s advisable to cut the meat into smaller chunks and place it in the freezer for about 30 minutes to an hour. This helps firm up the fat and meat, making it easier to grind without turning mushy.

- Chill the Grinder Parts: If possible, chill your grinder’s components (especially the blade and plate) in the freezer before use. This further reduces the chances of the meat warming up too quickly.

3. Blades and Plates: The Heart of Your Grinder

Grinder blades and plates are critical components that determine the quality of the meat grind. If your grinder’s blades are dull, they will not cut the meat cleanly, resulting in a mushy, pasty texture. Instead of cutting the fibers of the meat and fat, dull blades may mash them together. Similarly, the grinder plate’s size plays a significant role in the consistency of the grind. If you are using a plate with too fine a mesh, the grinder will produce a much smoother, softer product than desired.

Tips for Maintaining Blades and Plates:

- Sharpen the Blades: Dull blades lead to poor performance, so sharpen them regularly or replace them when they start to show signs of wear.

- Choose the Right Plate: Use a coarse plate for a rougher texture and switch to a finer plate only if necessary. A coarser grind will help maintain the structure of the meat, preventing it from becoming too mushy.

4. Grinding Meat in Stages: A Key to Consistency

If you’re grinding a large amount of meat, it can be tempting to try and grind it all at once. However, this is not always the best approach, as it can lead to uneven textures. Grinding meat in stages helps to manage the fat and meat more effectively, ensuring that the grind stays consistent.

Grinding in Stages:

- Start by passing the meat through a coarse plate to begin breaking it down. After the initial pass, you can grind it a second time using a finer plate if you want a smoother texture.

- This process helps prevent the grinder from overheating and minimizes the risk of the meat turning into mush, as it allows the fat and muscle fibers to be processed more gently.

5. Excessive Pressure: A Recipe for Disaster

Applying too much pressure when feeding meat into the grinder is a common mistake. While it might seem like a good idea to push the meat through more quickly, doing so can cause the grinder to overheat. The extra force can also lead to the fat and muscle tissue being forced through the grinding plates too quickly, resulting in a paste-like consistency.

How to Avoid Over-Pressuring Your Grinder:

- Let the grinder do the work. If you’re using an electric grinder, avoid forcing the meat into the chute. For manual grinders, turn the handle gently and steadily.

- If the grinder is struggling, pause, and check the temperature of the meat. Chilled meat and a slow, steady grinding pace will help you achieve the right texture.

6. Choosing the Right Grinder for the Job

Not all grinders are equal, and choosing the right one for the type of meat and volume you’re grinding is essential. Manual grinders, while inexpensive, are often not suitable for large batches or tougher cuts of meat. On the other hand, an electric grinder can make the process faster and more efficient but may struggle if it’s not powerful enough for your needs.

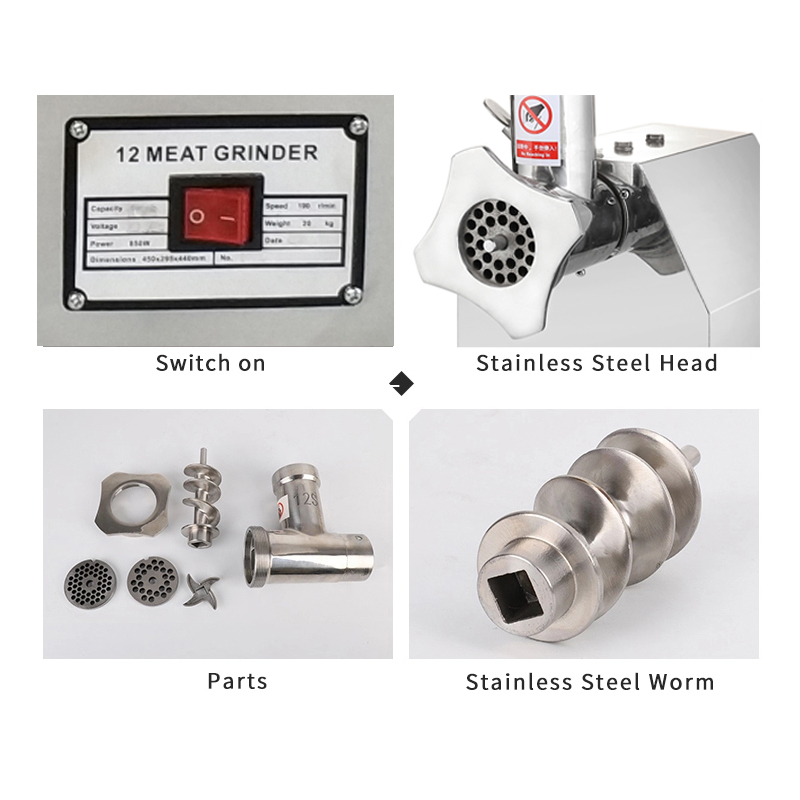

Key Features to Look for in a Grinder:

- Motor Power: If you frequently grind tougher cuts of meat or large quantities, opt for a grinder with a powerful motor to handle the load.

- Grinder Size: Larger grinders are more suited for professional-grade meat processing, while smaller grinders are sufficient for home use.

- Material Quality: Stainless steel blades and plates will perform better and last longer, especially with fatty cuts of meat.

7. Speed Matters: Adjusting Grinder Settings

Some high-end grinders come with variable speed settings. If your grinder offers multiple speeds, using a lower speed can help prevent the meat from mushing. High-speed grinding generates more heat, which can soften the fat and lead to mushy results. Slower speeds ensure that the grinder works at a more controlled pace, which helps preserve the integrity of the meat’s texture.

Conclusion: Mastering the Grind

The problem of mushy meat can be frustrating, but with the right approach, you can troubleshoot and solve this issue. By paying attention to the type and quality of meat you’re using, ensuring the meat is chilled properly, maintaining your grinder’s blades and plates, and using the correct grinding techniques, you can achieve the perfect grind for any recipe. Whether you’re making sausages, burgers, or just ground beef for your favorite dishes, a few simple adjustments will ensure that your meat grinder delivers excellent results every time.